We celebrate 70 years of innovation, cooperation and success.

70 years of Styropor® from live-saver to thermal insulation: For 70 years Styropor® protects various applications - for 70 years Styropor® is an important part of our everyday life.

ELEMENTary – a BASF podcast

The BASF podcast "ELEMENTary" is about chemistry that connects - for a sustainable future. Listen to our latest episode: 70 Jahre Styropor®

The BASF podcast "ELEMENTary" is about chemistry that connects - for a sustainable future. Listen to our latest episode: 70 Jahre Styropor®

Podcast sequence only in german.

From a chance find to a plastics classic

70 years of Styropor® - that's 70 years full of stories, further developments and innovations. In our BASFinside film, we look back at the early years of the century-old invention, how it has evolved to the present day and what important role Styropor® still plays in our lives today.

Film only in german

Styropor® in the art scene

Our white classic is not only part of our everyday life, it is also used in extraordinary areas. For artists worldwide, Styropor® is a popular material. In our interview series, artists tell why and how they use Styropor® to create impressive works of art. Go to interviews

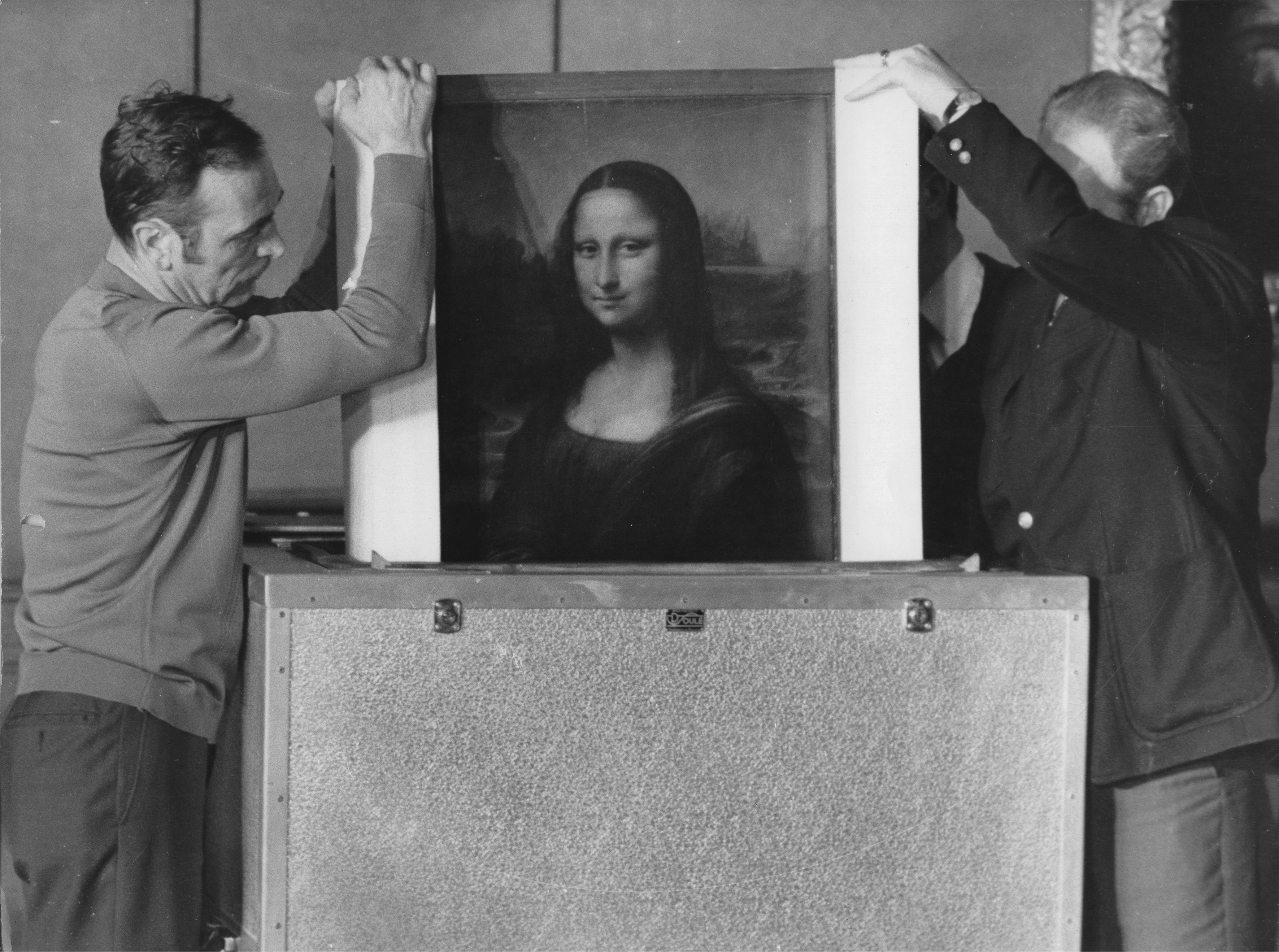

#Milestones

Lots of milestones are behind us – but we are convinced that there are many more milestones ahead with Styropor® and Neopor®.

Styropor® and Neopor®: Important part of countless applications – important part of our everyday life.

TOP